Premium litho printing Services for Professional Results

A Comprehensive Guide to Understanding Litho Printing Techniques

The globe of litho printing, a strategy stemming from the late 18th century, is an interesting mix of history, innovation, scientific research and art. Stay with us as we journey into the captivating world of litho printing.

The Historic Advancement of Litho Printing

The historic trajectory of litho printing, a crucial advancement in the realm of communication, is a captivating tale of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this technique was initially an economical technique of publishing staged works. Lithography, originated from the Greek words for 'rock' and 'to compose', made use of a smooth stone surface to transfer photos onto paper. The process progressed with the introduction of the rotary press, which significantly raised productivity (litho printing). In the 20th century, the innovation of balanced out lithography changed the market, permitting for automation of high-quality prints. Each stage of litho printing's advancement showcases humankind's ruthless search of effectiveness and top quality in visual communication.

Deciphering the Science Behind Litho Printing Inks

Moving on in the expedition of litho printing methods, the focus currently shifts to the scientific research behind litho printing inks. The structure of these inks, their drying procedure, and color mixing strategies create the backbone of this complex art kind. Comprehending these elements is critical to understanding the craft and accomplishing the wanted print outcomes.

Make-up of Litho Inks

In lithographic printing, the basic duty of litho inks can not be overemphasized. Pigments, the color-providing elements, are carefully ground fragments put on hold in the vehicle, a fluid that lugs the pigment onto the printing surface. Each part plays an important component in the last print's high quality, making the specific formulation of litho inks an intricate science.

Ink Drying Refine

From the structure of litho inks, attention turns to the fascinating process of ink drying out. The drying procedure is critical, as it influences the last print's high quality and durability. 2 main approaches are made use of in litho printing: oxidative drying and absorption. Oxidative drying entails the ink responding with oxygen in the air to develop a hard, completely dry film. This approach provides a sturdy surface, however can be slower contrasted to absorption. Absorption, on the various other hand, entails the ink permeating into the paper fibers, which is a quicker procedure yet can bring about less vibrant shades. The selection between these methods is dependent upon elements such as print rate needs, the paper type utilized, and the desired coating.

Shade Combining Strategies

While the drying out process plays a key function in litho printing, the science of shade blending methods holds equivalent relevance. The science behind litho printing inks also takes right into account the openness of the ink, which influences exactly how shades overlay and mix.

The Art and Design Aspects in Litho Printing

Litho printing takes a breath life right into art and layout with its distinct aspects. The procedure involves developing an image on a lithographic sedimentary rock plate or metal plate with a smooth surface. The photo is after that printed onto a tool, usually paper, by transferring the ink from home plate. What sets litho printing apart is its capability to duplicate detailed styles with high fidelity, making the result practically similar to the original art work. This is attained with the usage of different line strategies such as hatching, cross-hatching, and stippling, which allow for a variety of tonal impacts. Litho printing accommodates a range of colors, making it possible for artists to produce vibrant and dynamic prints. This mix of precision and flexibility makes litho printing a preferred choice for lots of artists and designers.

Modern Applications of Litho Printing Techniques

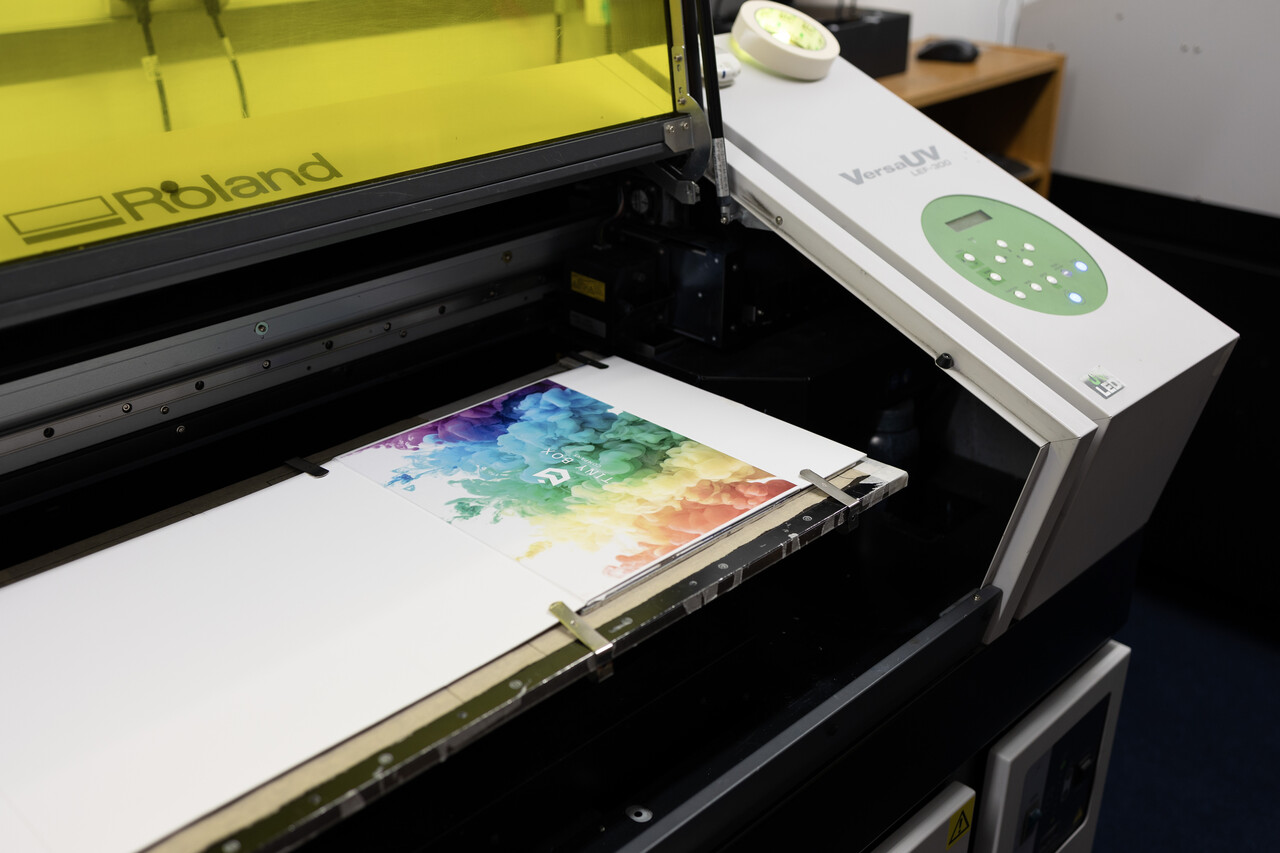

Litho printing techniques have discovered considerable use in the modern-day commercial field. Its impact and value remain to grow with the advent of brand-new technologies and innovations in the area. This section will check out these modern applications and the transformative role they play in the printing industry.

Commercial Litho Printing Makes Use Of

Litho printing stays a vital component of the industrial field. High-volume printing jobs, such as the manufacturing website here of publications, newspapers, and packaging, count on litho printing for its capability to provide exceptional photo quality and expense effectiveness. Litho printing additionally provides a broad shade range, exceptional to that of electronic printing.

Innovations in Litho Printing

Pushing the borders of traditional techniques, modern-day advancements have actually fueled a host of developments in litho printing. One prominent development is electronic litho printing, which integrates the merits of electronic modern technology with litho's high-quality result. These developments emphasize the long-lasting significance of litho printing in the modern world.

Exploring the Refine of Litho Printing: Step by Step

Obstacles and Solutions in Contemporary Litho Printing

Despite the accuracy and tradition that litho printing proudly maintains, it is not without its collection of contemporary difficulties. One of the most common concerns consist of the high first configuration cost, problem in printing variable data, and ecological concerns as a result of chemical usage. Solutions are emerging as modern technology evolves. Digital litho printing enables for economical brief runs and easy personalization, attending to the concern official site of variable data. Environmentally-friendly inks and more secure plate-making processes mitigate ecological problems. Furthermore, developments in automation have reduced labor expenses, better democratizing the lithography process. Therefore, while there are obstacles, the litho printing market is proactively adjusting to meet them head-on, guaranteeing its relevance in the future.

Verdict

Finally, litho printing, with its rich background and scientific intricacies, holds a significant place in the print sector. As the guide discloses, it's a synthesis of art and technology, with contemporary innovations guaranteeing its importance. Nevertheless, the industry deals with challenges that call for ingenious solutions, with a concentrate on automation and sustainability. The future of see this site litho printing hinges on its capacity to adjust to these altering demands, affirming its long-lasting worth in a progressing market.